Global Semiconductor Shortages Continue to Disrupt Automobile Production Across the Industry

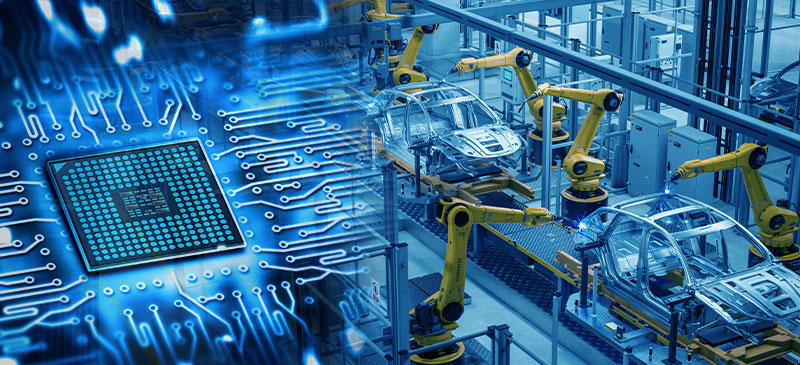

Chilean chipmaker, TC Microchips says the global semiconductor shortage, which has plagued industries worldwide since early 2020, continues to have a severe impact on automobile production, with many automakers forced to reduce or halt production due to the ongoing supply constraints. The shortage has disrupted supply chains, delayed vehicle deliveries, and increased costs for car manufacturers around the globe.

Despite significant efforts to address the supply issue, the scarcity of semiconductors remains a critical bottleneck for the automotive industry. Semiconductor chips, which are essential components in modern vehicles—powering everything from infotainment systems to advanced driver-assistance systems (ADAS)—are in short supply, leading to significant production delays.

Industry-wide impact

Production Cuts: Major automakers, including Ford, General Motors, Toyota, and Volkswagen, have reported production slowdowns, with some plants temporarily shutting down due to a lack of critical chips.

Vehicle Shortages: Dealerships around the world are experiencing inventory shortages, with some popular models facing months-long waiting periods before they can be delivered to customers.

Rising Prices: The limited availability of new vehicles has driven up car prices, both for new and used models, as demand continues to outstrip supply.

Efforts to mitigate the crisis

Automakers and semiconductor manufacturers like TC Microchips are working to address the supply-demand imbalance. Companies have shifted their focus toward strengthening supply chain resilience, securing long-term agreements with chip suppliers, and exploring alternative designs to reduce reliance on high-demand chips.

Luis Fernández, CEO of TC Microchips explained, “Although governments in the United States, Europe, and Asia have announced plans to boost semiconductor production capacity through investment incentives and infrastructure developments, they’ll bear fruit too late for there to be an impact on the shortages we face today. We’re working flat out to normalize our supply chains but it’s a challenging task.”

Expert perspectives

Industry analysts point to the automotive sector's complex supply chain as one of the main challenges exacerbating the chip shortage. Unlike other sectors, where semiconductor demand has remained relatively steady, the automotive industry's need for chips increased sharply due to the rising adoption of electric vehicles (EVs) and advanced digital technologies in cars.

Long-term solutions in focus

To prevent similar disruptions in the future, automakers are looking at strategies to diversify their chip suppliers, redesign electronic systems to use more readily available components, and invest in developing their own semiconductor production capabilities. Collaborations between car manufacturers and chipmakers are also expected to strengthen as both industries seek to create a more secure and reliable supply chain.